Ana amfani da ERNiFe-CI don walda baƙin ƙarfe.Ana amfani da wannan ƙarfe da yawa don rufe juzu'in simintin ƙarfe.Hakanan ana amfani dashi don gyara simintin gyaran kafa.Ana ba da shawarar zafin zafi da zafin jiki na 175ºC (350ºF) mafi ƙanƙanta yayin waldawa, in ba tare da abin da yankin ya shafa na walda da zafi na iya haɓaka fasa ba.

Ni 55 (AWS class ba a kayyade ba) waya ce ta nickel mai suna 55%.Ƙananan abun ciki na nickel yana sa wannan gami ya fi Ni 99 tattalin arziki. Weld adibas yawanci na'ura ne, amma a karkashin yanayi na high admixture, da welds iya zama wuya da kuma wuya na'ura.Ana amfani da shi sau da yawa don gyaran simintin gyaran kafa tare da sassa masu nauyi ko kauri.Idan aka kwatanta da Ni 99, welds da aka yi tare da 55 Ni sun fi ƙarfi kuma sun fi ductile, kuma sun fi jure wa phosphorous a simintin.Hakanan yana da ƙarancin haɓakar haɓakawa fiye da Ni 99, wanda ke haifar da ƙarancin faɗuwar layin fusion.

HADIN KASHI:

| NickelNi45.0-60.0% | IronFebalance | SiliconSimax 4.0% | ManganeseMn2.5% | CopperCu2.5% | CarbonCmax 2.0% | AluminumAlmax 1.0% |

KAYAN KANikanci:

| Ƙarfin Tensile Rm (MPa) | Ƙarfin Haɓaka Rp0.2 (MPa) | Tsawaita A % |

| min.393-579 (57-84 psi) | 296-434 (40-64 psi) | 6-13 |

SIFFOFIN KIRKI:

| Samfura | Diamita, mm | Tsawon, mm |

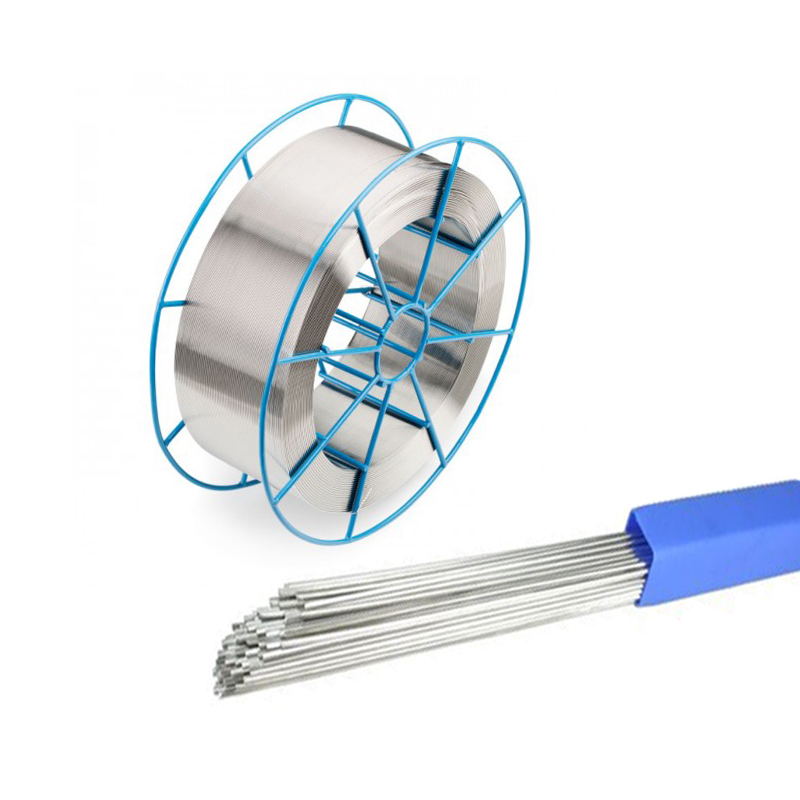

| Waya don walda MIG/GMAW | 0.8, 1.0, 1.2, 1.6, 2.0, 2.4, 2.5, 3.2 | - |

| Sanduna don TIG/GTW waldi | 2.0, 2.5, 3.2, 4.0, 5.0 | 915-1000 |

| Waya don walda SAW | 2.0, 2.4, 3.2, 4.0, 5.0 | - |

| Electrode core waya | 2.0, 2.5, 3.20, 3.25, 4.0, 5.0 | 250, 300, 350, 400, 450, 500 |

Binary Nickel-Iron (Ni-Fe) da Ni-Fe na tushen hadaddun gami da hadaddun walda ana kawo su cikin sandar walda da wayoyi a daidaitaccen tsayi ko tsayi har zuwa buƙatun masu amfani.Don yanayin sabis na yau da kullun, abubuwan haɗin sinadarai suna samuwa a cikin nau'ikan Ni daban-daban bisa ga mafi yawan ƙa'idodin Amurka da Turai.